Back Manufacturing Resources Planning German برنامهریزی منابع تولید Persian Manufacturing Resource Planning ID Manufacturing Resource Planning Italian Manufacturing resources planning Dutch Planowanie zasobów wytwórczych Polish Manufacturing resource planning Portuguese MRP II Russian İmalat kaynak planlaması Turkish MRP II Ukrainian

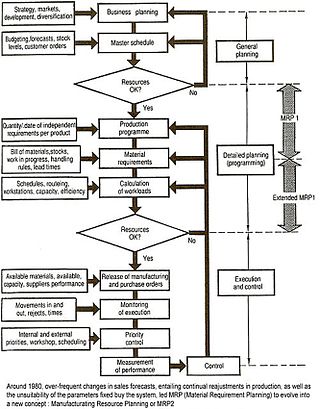

Manufacturing resource planning (MRP II)[1] is a method for the effective planning of all resources of a manufacturing company. Ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer "what-if" questions and is an extension of closed-loop MRP (Material Requirements Planning).[2]

This is not exclusively a software function, but the management of people skills, requiring a dedication to database accuracy, and sufficient computer resources. It is a total company management concept for using human and company resources more productively.

- ^ Chris Kraul (March 22, 1989). "DataWorks of San Diego, a closely held ..." The Los Angeles Times.

- ^ Christopher Gray; Darryl Landvater. "MRP II: The History, The Problems, The Future". Computerworld.